Main benefits

- Plug-and-pump installation

Plug in without worrying about overheating. Built-in contactor and thermal sensors protects the motor from overheating. Pumps with a built-in AquaTronic unit will electronically adjust for incorrect phase order, ensuring correct impeller rotation.

- Reliable and trouble-free operation

Equipped with a free flow vortex impeller and a pump volute, the XJS is perfect for pumping sludge and water mixed with solids. The pump design, robust construction and premium materials ensure high wear resistance. The impeller is available in different sizes to meet your specific requirement. Min impeller diameter for duty with low water level or intermittent dry running. Max impeller diameter requires half motor or more submersed for continuous duty. (Pump can operate lying down)

- Serviceability

The modular design of the pump range saves cost by ensuring maximum pump availability with a smaller spare parts inventory.The condition of a pump with a built-in AquaTronic unit can rapidly be checked without disassembly, using its service software.

- Saves energy and the environment

The high-efficiency motor and hydraulics are combined with low friction bearings to reduce power losses. You achieve low total energy costs and minimize your carbon footprint. Environmentally safe white oil is used in the oil casing for easy inspection of seal conditions.

|

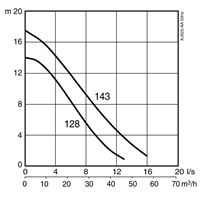

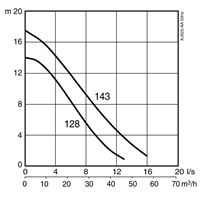

XJS 25 Curve 50Hz |

Product information

Submersible Sludge Pump XJS 25 – 50Hz

Models

| XJS 25 D -128, 3-phase |

| XJS 25 D -128 AT* 3-phase |

| XJS 25 D -143, 3-phase |

| XJS 25 D -143 AT* 3-phase |

| Weight: 39 kg |

*AquaTronic: Built in electronic pump control.

Specification

Electric submersible pump

| Maximum submergence |

20 m |

| Protection class |

IP 68

|

| Max. temperature of pumped medium at max. power input and continuous duty |

40ºC

|

| Max. medium density |

1.100 kg/m3

|

| pH of the pumped medium |

5-8

|

| Free passage |

45 x 55 mm

|

| Max number of starts |

30/hour |

| Motor rating P2 |

2.5 kW |

| Speed |

2920 rpm |

| Power cable |

20 m type H07RN8-F |

Starting Method and Motor Protection

XJS 25 AT: Direct on line start (DOL 230-550 V) with built in AquaTronic unit, which automatically adjusts phase order by dual contactors, ensuring correct motor rotation. The AquaTronic unit monitors motor temperature, by use of NTC thermistors built into stator windings, and stops the motor at high temperature. It will also stop the motor at high amperage or if a phase is missing.

XJS 25: Direct on line start with built in contactor. Pumps to be used with VFD or 1000 V must have terminal block instead of contactor.

Thermal switches (140 ºC, ±5) built into the stator windings are connected to the contactor and stops the pump at high temperature.

Discharge Connections

2 1/2”, 3” (standard), 4” hose connections

|

| 2 1/2”, 3”, 4” G/B.S.P. threaded connections |